-edible zone-

No.6435 Overview

Starting Line

Arrival Deconstruction

Beneath Decks

First Night's Spin

Listening to Plinths

Motor

System: The Tonearm Tweaks Articles

Bookshelf

Transit

*

COMPLETE DISASSEMBLY & stripdown of spindle

bearing.

Somewhat easier than it seems …… From below, the whole

grease jet and it’s cap must first be removed to allow clearance for the

assembly to be extracted through the top deck. This seems intimidating,

at first, until you remember that it is a grease bearing, and not filled

with oil or anything that’s going to run all over uncontrollably. Even

broken-down grease remains pretty manageable.

Something I've gone

all-out on is to mark or note the exact position / orientation of parts

that might have two or more ways to go back together. This is all under

the hood, so my little directional triangles and dots will never show on

the finished deck. The rationale here is that things tend to wear in to

a certain mode of fitting, especially on a fifty-year old unit. I won't

be disturbing their style at this point.

The grease I've chosen as

replacement is an assemblage of negatives--- that is, there's no PTFE,

no Teflon, no Moly, no additives. Pure black petroleum distillate ---

plain and unimproved is what I was after. The idea I've gotten from

researching this --and will go with-- is that the lubes used herein

should contain nothing that similar weights of lube wouldn't contain

back in 1955, when this was manufactured. Use nothing that could

possibly do harm.

THERE IS NO BEARING (ball) in a grease bearing.

... I suspected that I'd have to soak the bearing elements in some

solvent ( I opted for plain Zippo lighter fluid (naptha) in this case.

I've used it for years on everything and I know from Lp-cover adhesive

removal that it evaporates quickly and leaves no visable residue of it's

own, even on a white Lp cover.)---- but soon found that the old greases

just slid off the HYPER-POLISHED MIRROR-FINISH hardened steel spindle

shaft. This particular part of the Garrard, along with the interior

polished-brass sleeve, is one of the most highly-finished / precise

parts I've ever seen in any field short of aerospace; certainly blows

away any 'record player' elements I've ever seen. A Zippo-soaked cloth

finishes the cleanup of the bearing-shaft interior.

Most

intriguing, though, is the lack of any thrust-ball arrangement below the

central spindle. The super-polished base of the spindle shaft sits

squarely (roundly ?) on a small phosphor-bronze thrust-pad and rotates

on that surface, flat-base on flat-pad, courtesy of the pressurized

grease surrounding and submersing the whole column.

GREASE is the

word.

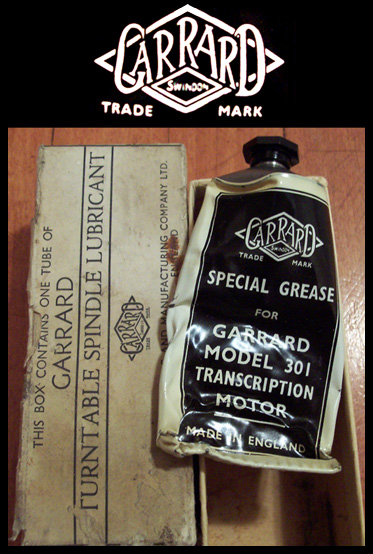

Garrard originally included a tube of their exact

specification of bearing grease, nozzle appropriately sized for

injecting the bearing periodically. Lacking either the

appropriately-nozzled grease-gun or the long-gone accessory tube of

Garrard Grease, the best way to cram this thing full of grease was by a

longish 'coffee stirrer' stick, the wooden one that's about one-eighth

inch wide by five or so inches long. With this implement it's pretty

simple to "paint" a thick inner layer all the way through the inside

length of the bearing housing. Go over the top a little here, as the

object is to eliminate all air once the spindle shaft is re-inserted.

The reinsertion is somewhat tantric and takes a few minutes for the

shaft to penetrate. This is fine because the side-loader jet and cap may

be filled w/ the black stuff and coaxed onboard while the shaft is still

coming through. But first check the progress through the port, which

actually allows a side-view of the progress as it goes.

Be prepared for the top-deck-side spindle to

emerge super-well-gunked, and have the materials on hand for tidying up.

Again, simpler than it all sounds, since you can slow the progress of

the spindle shaft at any time by leaning more to the horizontal, which

causes it to stop pretty quickly. Any apprehension about a

grease-bearing changeout is pretty soon dispelled.

With motor

unplugged and switch to off, replace platter, and only then switch to on

(still unplugged). By manually rotating platter, the grease-blanket

inside the

bearing is evening itself out, hopefully sending any

air pocket out the top, where you'll find a new, liquid

residue

of black grease that has come all the way through the bearing. That's

correct. This leaks out of the top . Tighten up a little on the

grease-jet on the side of the assembly and more and more of the grease

works it's way through, and then out, of the top.

Keep mopping

up, replacing platter and repeating manual rotation.

One wants to

get grease into every spare millimeter of the interior space of the

bearing. All should be reassembled once grease is repacked; note

orientation markers & arrows. Do take care to set on off switch

accordingly. In "off" the small platter brake is on, but you may place

and replace platter gently, again, always favoring rotation toward

clockwise. In "on" the brake is off but-- the whole motor / idler

assembly is engaged, so be aware that even with power off, there's a lot

going on.....

Next Page .... Beneath Decks