-edible zone-

-- Receiving

Receiving

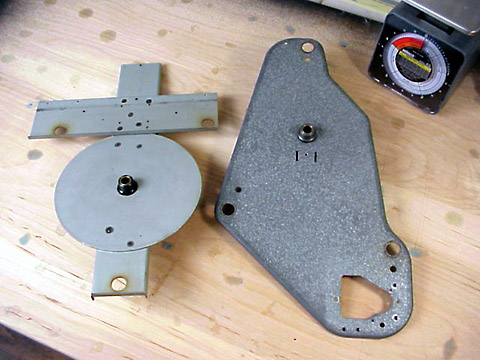

-- The TD150 mkII Subchassis and Bearing

- Some stats for the TD150 Mk II subchassis:

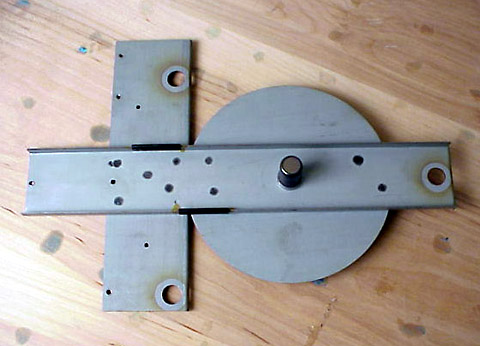

- Weight: 1 pound 14 ounces (bare with bearing mounted and as pictured)

- material: Steel (alloy unknown. magnet sticks) appears to be plated, hardness unknown

- material thickness: .06 inches all over

- fabrication: a 3 piece (less bearing) spot welded assembly

- deflection under load of its own inner and outer platters (static load test)

*

(hint: click thumbnail for full image)

(hint: click thumbnail for full image)

*

-- This part feels stout when held by hand. The structural

integrity seems pretty fair. However, when put to a deflection

under load test of its own platter system, some flexing was seen.

-- (See test page for the gory details)

* Weight bare chassis with brg. housing: 1 pound 14 ounces.

Weight bare chassis with brg. housing: 1 pound 14 ounces.

*

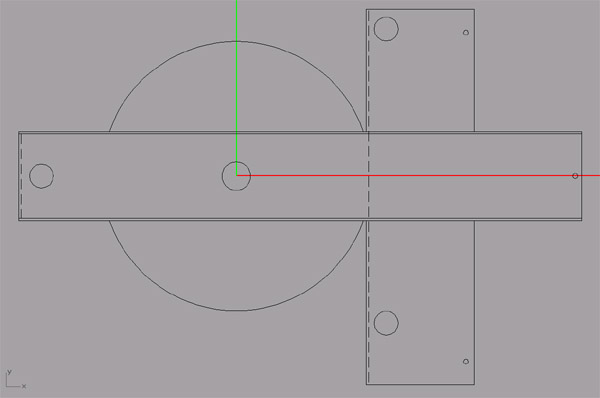

-- Above: bottom view, TD150 mkII subchassis

*

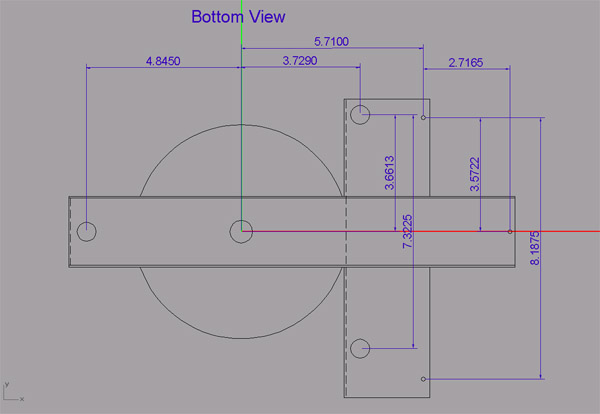

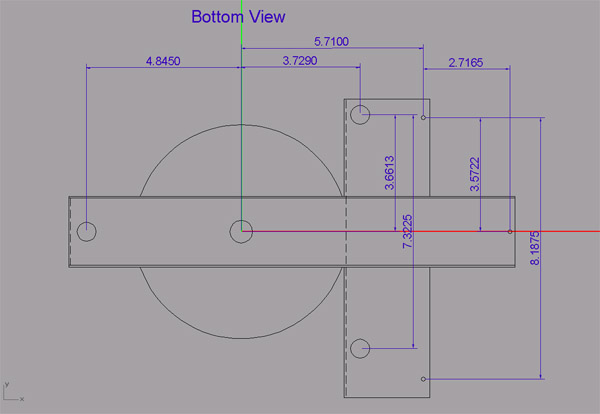

-- Above: Hole location dimensions, in inches, taken from the sample

*

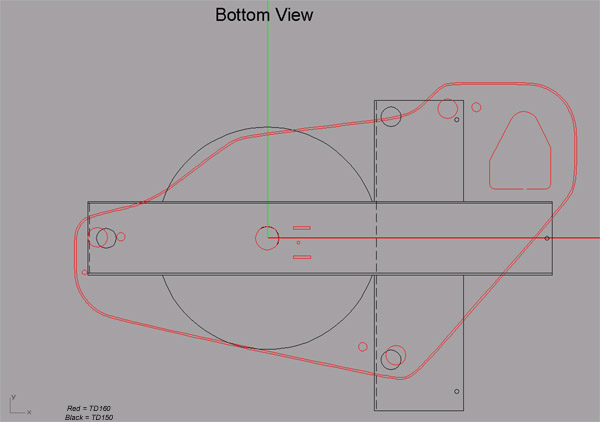

-- Above: Overlay, TD160 subchassis over the TD150

* (click thumbnail for full size image)

(click thumbnail for full size image)

*

--The TD160 bearing housing appears to be nearly identical to that of the TD150.

--Some stats for the TD160 mk II subchassis pictured above:

- weight: 1 pound 8 ounces (bare with bearing mounted as pictured)

- material: Steel (alloy unknown. magnet sticks) appears to be plated, hardness unknown

- material thickness: .056 inches all over

- fabrication: a single piece (less bearing) sheet metal stamping

- deflection under the load of its own inner and outer platters: static load test

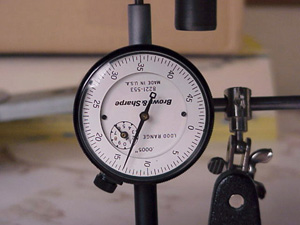

* Testing the subchassis for deflection under load. I was curious to

see if the subchassis framework would flex under the load of its own

platter and armboard.....and, like the TD150 subchassis, it did.

Testing the subchassis for deflection under load. I was curious to

see if the subchassis framework would flex under the load of its own

platter and armboard.....and, like the TD150 subchassis, it did.

________________________________________________horizontal rule

*Looking at the suspension

1)

-- Above photo #1 shows the underside of the table, just prior

starting the stage 2 sessions. The object being to set the table up in

near stock configuration, align it and then just listen for a few days

to get some sense of the deck's signature sound. Springs and rubbers

have been cleaned and powdered (talc). An arm board has been cut from

3/8 inch thick grade LE phenolic. The SME 3009 S2i tonearm has been

mounted. The suspension has been leveled and tuned for vertical bounce

action.

It is at this point that I notice, when looking at this

view from underneath, the three very different spring adjustments. It is

very clear that the spring nearest the tonearm is taking more weight

than the other two springs. In another project, I had weighed this

tonearm and compared the weight to the Thorens TP16 tonearm. The SME was

heavier by a few ounces. However the TD150 Mk II does not use the TP16.

It used the TP13A. I don't know the weight of that arm but assume it

must be substantially lighter.

2)

-- Above illustration #2. A cad drawing of the subchassis that shows

the spring locations relative to the spindle bearing. It appears that

the two arm board springs are located closer to the bearing than the far

spring. I think this spacing will result in an uneven spring loading

even when the standard arm and board is being carried.

-- In

spite of the uneven spring loading, it is possible to get a "mainly"

vertical bounce action with careful tuning of the springs, their height

adjustment and by centering the spring around the stud that holds it.

However, it isn't possible to get a true "piston" action. Instead, the

bounce action of the armboard and platter may be observed as relatively

even but with some difference in timing. The tonearm end will crest just

slightly behind the unloaded end of the arm board. The platter crests at

a slightly different time. This results in a slight jiggle. The jiggle

can be reduced substantially thru careful tuning as described above, but

not completely eliminated.

-- My take is that a true up/down

piston action will not occur until the mass of the suspended elements is

centered between the three springs. I can think of two ways to achieve

this.

1) The first, and easiest, is to fix additional weights to

the subchassis next to 2 of the lighter loaded springs. The object being

to load each of the three springs with equal weight.

2) The

second, and more elaborate, would not only balance the weight load

between the three springs, but place the mass center lower within the

vertical dimensions of the box. I can envision this as a second frame

attached under the upper existing frame. Provision could be made for a

moveable weight to help find a precise mass center. The lower the center

of gravity, the more control will be had over bounce action. Do this

right and the under frame could also serve to stiffen the upper frame.

-- However, I'm thinking ahead. I have seen similar spring loading

issues when tuning my TD160. The spring nearest the arm board seems to

be taking a heavier load. I feel that this may be inherent in the

design. Call it a weakness of the table. We have already seen another

weakness with regard to subchassis rigidity. I will accept the above

limitation for the time being, but down the road, if significant sonic

improvements are to be achieved, a re-design of the subchassis needs to

be done so that each of the three springs are loaded equally and that

the mass center is as low as is possible within the confines of the

cabinet interior.

-- Clean-up and prep

-- Step 2: Play and listen before the

upgrades

-- Early listening impressions.

-- Sited on a

wall shelf and spinning some Freddy Hubbard. I have one of Ken Lyon's

Neuance shelves under it. I used the Neuance with the TD160 in this same

location just prior to obtaining the TD150.

-- Early Listening:

-- The area foot print of this deck is smaller than that of its

successor, the TD160. In the vertical, cabinet height is also smaller.

What isn't smaller is the sound this little turntable can produce.

Compared to the TD160, the overall sonic picture seems slightly

brighter. Highs are less rolled off. The Shure V15VxMR is a factor here,

but I've used the same arm, cart and phono stage combo on both tables.

Comparisons are valid. Dynamics seem good. Attack, sustain and decay

qualities are slightly sharper in attack, clean and unwavering in

sustain and then about the same in decay. Detail levels are also good

for the cartridge, arm and phono stage combination in use. There is a

good, if not better, sense of timbre and texture. And this is with a

nearly stock table...! The arm is the SME 3009 S2 improved with fixed

headshell.

-- The SME tonearm mounts near the extremes of the

armboard. This was also the case when fitting the same arm to the TD160

but the larger, open armboard area of the TD150 makes tonearm mounting

infinitely more simple. Once fitted operation is quite good. Cueing

operation was convenient and stable.

--

The motor: I don't think it is

accurate to say that the TD160 and TD150 share the same motor. Yes, they

are both 16-pole AC synchronous motors. That much they have in common.

The shape of the TD150 motor housing appears identical to that of the

TD125 (first version). This is quite different from the TD16x series

motors which have a triangular shaped case work. The motor drive pulley

is lathe turned from solid aluminum. With the TD16x series you get a

plastic injection molded clutch pulley. I'm not saying that is bad, it

is just what you get. The motor torque is quite low on this TD150. With

belt off and motor spinning at 33-1/3, I can lightly pinch the pulley

between thumb and forefinger and thus stop the motor from spinning.

Easily. I checked to make sure if there was any slippage between pulley

and the motor shaft by marking the shaft and pulley. No slip. This motor

just has very little torque. Listening to music my ears tell me this

must be good.

-- The platter bearing:

-- I have already

determined the spindle shaft and bushings to be in excellent, unworn

condition. I put some fresh 20 wt. oil into the bearing housing well,

then placed the spindle shaft, with inner platter attached, into the

bearing housing and let it slide down to the pool of oil. The shaft

floats on top of the oil at first then, slowly, the lube passes by the

narrow clearance between bushing and shaft and allows the spindle

bearing tip to reach home against the thrust plate. When I get some

excess oil overflowing out of the bearing housing I know I have enough

lube in there for the upper bushing to stay bathed in oil.

-- The

footers and bottom cover:

-- This deck came without a bottom

cover as well. Naturally I was going to replace that too. The footers I

found on the deck are the simple but thick and solid rubber furniture

feet that have a self adhesive side and have been stuck to the four

corner braces within the cabinet directly over the mounting holes for

the standard feet. While kind of cheesy, these feet do not suffer from

any lack of solidness. I will replace these when the new cabinet with

new bottom cover is fabricated. They'll work for the time being.

I bought the deck without armboard or arm. I provide both. For

armboard material I am using 3/8 inch thick grade LE canvas /phenolic as

the base material and then a smaller piece of 1/8th inch thick carbon

fiber to mount the arm to. This results in a very stiff platform to hold

the arm. Enough with the explanations. I'll just listen to this little

table for a day or two before going to the next step. It's a good

one...!

-- Thinking About Springs

*

-- Above: the standard TD150 frame 3d cad dwg. drawn by site owner.

-- Data for the standard Thorens TD150 spring:

- Type: conical compression, ground ends, open

- wire alloy: unknown but it is steel (a magnet sticks) and is not rusty after 30 years of use.

- No. of working coils: 11

- mean diameter at small end: .602 inches

- mean diameter at large end: .906 inches

- avg mean diameter: .754

- wire diameter: .059 inches

- free length: 1.935

- spring index: 13,,,?

- static deflection : .5 to .7 inches in the standard setup (see image # 1) (varies from spring to spring)

- spring rate: ?

- natural frequency: estimated 4 to 6 hz

-- More notes:

-- The three springs carry the tonearm,

which has an arm/cartridge natural resonance of between 8 to 12 hz, This

is an industry standard but may vary outside this range if arm and

cartridge are not well matched.

-- Footfall resonance is,

around the web, popularly thought to be approximately 3 hz but will not

be an issue as the turntable can be mounted from the wall.

--

Even more notes about springs:

-- Spring stiffness is expressed

in terms of how much force is needed to compress a spring one inch. If a

spring is rated at 4 lbs, this means that it takes 4 lbs of pressure to

deflect the spring one inch.

-- Static deflection is the amount

of distance the spring is compressed when under a normal load and at

rest.

-- Natural frequency is the number of oscillations a spring

will go through under a given load.

-- Some formulas for

calculating natural frequency:

- NF = natural frequency in hz

- K = spring stiffness

- DST = Static Deflection

- hz = cycles per second

-- NF = 3.13 SQRT K/load

-- or

-- NF = 3.13 / sqrt

DST (in inches)

-- or

-- NF = 5 sqrt 1/DST (in cm)

-- The

natural frequency of the sprung suspension should exist between foot

fall and the cart/arm natural frequency. If foot fall is approximately 3

hz and the low end of cart/arm frequency is 8 hz, then the target for

spring frequency is 4 - 6 hz.

-- But.....Does it have to be

Springs?

-- Hmmm. Tired of calculating spring rates, natural

frequencies...? Tired of periodic suspension tuning...?

-- I

thought I would try an 'isolator grommet' rather than a spring just to

see how it sounds. These grommets do isolate between the subchassis and

the motor plate. I suppose it could still be called a suspended design

because the subchassis is carried by the grommets.

* Left: the "heater hose" isolator.

Left: the "heater hose" isolator.

-- The above

idea uses a pair of the large Thorens rubber spring grommets and a

length of automotive heater hose cut square and then fitted in between

at the three spring locations. I calculate the natural frequency of this

spring to be less than, ummmm 1 hz....;-) OK, it doesn't oscillate at

all. Stethoscope listening suggests that motor vibes aren't getting into

the subchassis plate this way.

-- Ok, so I've played some vinyl in this

configuration and have noticed a background noise level comparable to

that of a 'spring equipped' TD150.... or maybe the 'sprung' TT actually

does have a quieter noise floor. But with the heater-hose mod the

sense of timing and articulation of detail seemed perhaps a tad sharper.

-- Who says the isolation has to

be by way of springs anyway....? But what about acoustic feedback? The

sprung suspension does offer at least some isolation from airborne sound

waves.

-- Note: I tried this for a while and after some

considerable time went back to the original subchassis and spring setup.

Bass was a bit better with springs. I have tried different conical coil

springs. At one time a set of Linn LP12 springs. Those were far stiffer

than the oem Thorens TD150 springs. I'm not ready to say which spring

was preferable. The stiffer Linn springs were less affected by foot fall

in that room with the flexy flooring and when not siting the turntable

to a wall shelf. Something I do from time to time.