-edible zone-

For those of us living on springy floors, the simplest and best solution to foot fall induced stylus skipping is to mount the turntable on a wall shelf. Dedicated turntable wall shelves are available commercially and tend to cost between $100 and $$everal hundred dollars (US) depending on design and manufacturer. Due to the simplicity of construction, building a turntable shelf DIY style is an easy project to undertake. It can potentially be much cheaper than going the commercial route, and the results can be very very good. The examples below are some ideas that I've tried.

Here is the first shelf. Home Depot 1/4 inch steel brackets lag

bolted to studs behind drywall. Two layers of 1/2 inch birch plywood

with a 2 inch thick layer of Y20 dense foam rubber. The larger

constrained layer shelf.

Directly under the Thorens TD160 MK 1 is

a Brite Star Iso-Rock platform which employs a sandwich of

mdf/sorbothane/mdf .,,,Another constrained layer shelf.

Mounting

from the structure of the wall eliminated the foot fall issues I was

having, allowing the Thorens to play undisturbed by vibes that

previously, were constantly working it's suspension. Sonic improvements

were apparent in terms of the sense of pace, detail articulation.

improved speed/pitch stability.

How about an air suspension turntable shelf...? Cheap too.

(click thumbnail for full size image)

(click thumbnail for full size image)

Supply list:

Brackets: 1/4 inch steel flat-bar from

Home Depot. size is 18 inch.

Stud Finder: Home Depot, again.

Electronic stud finder less than $10.00.

Bolts: 3/16 x 2-1.2 inch lag

bolt. (6 used. 3 each bracket to tie brkt's to studs behind sheetrock.)

Carpenters level for getting shelf level.

#10 Wood Screws to secure

lower shelf to brackets.

Shelf material: Grade A Birch ply, 12mm inch

thick.

Inner-tubes: 3 hand truck inner-tubes from Home Depot

(again..)

Blue Tack: between brackets and wall, brackets and shelf

Fabric Covering: optional. I've got green leather (cowhide) here. It

would be possible to construct the top shelf with side covers and a

laminate surface texture of your choice. Many options.

Notes:

1) Proximity to room corner makes tonearm/cartridge

susceptible to standing wave resonance. On the other hand, the corner

offers best possible structural integrity of supporting wall studs. A

compromise.

2) Recognizing that the brackets and plywood by

themselves would not provide optimum isolation from surface borne

vibrations off the wall, I added the inner-tubes and a second shelf to

isolate. This did result in an audibly quieter (blacker) background.

3) Added benefit: One can set level of top layer by altering

inflation of tubes.

4) I inflated tubes with a very low air

pressure to make them a more compliant springing medium. Higher air

pressure would have firmer suspension. A bicycle pump works fine. A

small portable compressor is even better if you're lazy like me.

5) It would be entirely possible to inject liquid (using a syringe)

into the tubes in addition to or in place of air for a "different"

damped spring compliance. I've heard of people using vegetable oil. I

haven't tried this, but it remains an option. Leaks could be

catastrophic, however.

6) Variations on shelf material could be

used; acrylic, Corian, tempered glass, marble, various composites, etc.

Heavy MDF for shelf material...?

MDF (Medium Density Fiberboard) 3 inches thick. With area dimensions

of 20 inches wide by 30 inches long this amount of MDF weighs in at 50

lbs...! As such, the block is still only a fraction of what the weight

would be in granite. Total weight standing on the Home Depot brackets

with turntable is 80 lbs at minimum..

Method of construction:

4 layers of 3/4 inch MDF cut to 20 x 30 inch rectangles. Layers were

glued with contact cement and pressed together with the weight of

several paving blocks. After all layers were dry at least 24 hours, I

used an orbital sander to block out the four ends flat. Several coats of

primer sealer were applied to the ends to fill the end grain, hand

sanding between coats with a 6 inch board with fine cut sandpaper. Once

all areas were visibly flat, I applied two coats of flat black all over,

blocking the painted surface after the first coat with more fine cut

sandpaper and the six inch board. This was an easy project to do and the

MDF was cheap.

project update: This block of MDF ultimately ended

up out in the work shop to be used as a flat block surface for clamping

parts together in various glue-up projects. As an audio accessory, it

did not last long in the living room.

A sturdy wall mount support for the turntable

Design and

fabrication at: Chez The Analog Dept.

Below 3d imagery: This is a

support structure for the Teres turntable I bought. The cad render

pre-visualizes it. I had decided that I needed to wall mount my Teres in

my upstairs flat. Problem is, nobody sells a TT wall rack robust enough

so I might as well build one. That's what I was thinking. Or maybe I was

looking for an excuse to build one.

1)

Material is to be mild steel in 2 shapes. 1 inch square (.07 wall) seamless tubing, and 1/8 inch thick plate (2 different widths). The various pieces are to be welded together using a Victor oxy-acetylene set. The completed rack is to be bolted to the load bearing stud structure behind the sheetrock wall with six 5/16 x 3 inch lag bolts. (lag bolt = A kind of hex head bolt designed to screw securely into wood - note: requires a pilot hole prior to bolting in) The main goal is to maximize rigidity of the TT mount while isolating from floor vibrations. It's a very springy 3rd story floor. The four ball studs are designed to support a rigid granite plate shelf which in turn supports the turntable itself. The ball studs thread into coupling nuts which were welded to the interior of the square tubing.

2) 3)

3) (click thumbnail for full size image)

(click thumbnail for full size image)

Above: Two 3D renders pre-visualizing the finished assembly.

That's a Teres model 135 less tonearm on top of the platform.

Notes: 3D cad geometry created in Rhino 3D

OK - so much for 'virtual reality'. Next comes 'reality'.

4)

Six 5/16" lag bolts secure the frame to the 2x4 studs behind

the drywall firmly. It's a sturdy enough frame for an adult to do

gymnastics on. The actual fabrication process went ahead as planned. To

mitigate the frames' tendency toward ringing, (when struck) the internal

volumes of the tubes were injected with polyurethane expanding foam.

(product name: Great Stuff. Available at Home Depot and other similar

hardware and supply stores)

But wait!! Did somebody say

--ringing--? It seems that every material on Earth rings at one

resonance or another.

The polyurethane foam, once injected into

the interior volume of the square tubing, did dampen the frame's natural

ring tone. This could be observed by gently tapping the frame with

another steel object, like a wrench. The ring tone became of shorter

duration and of lesser loudness. Nonetheless, this framework still

rings. With all this in mind, it must be conceded that the above frame,

due to its tendency to transmit resonance freely, as do all metal tubes,

has a design flaw.

5)

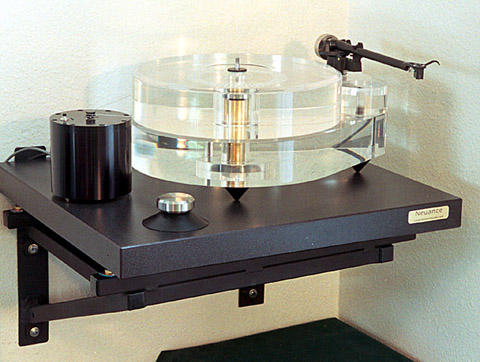

Photo #5) I had just received a Neuance shelf from Ken Lyons' company "Greater Ranges". Ken produces these excellent isolation shelves and sells them direct. Price is affordable.**

config 1) Neuance shelf directly over the four adjustable supports. (photo 5) The threaded studs with the brass acorn nuts made good supports for this shelf by allowing the shelf to be adjusted exactly level and also to set tension just right so that each 'foot' made solid equal contact with the shelf. Background isolation was excellent this way. Playing records I notice that there was a natural airy sound that, unfortunately, lacked low frequency slam.

6)

Photo #6) Trying the frame with a 3 x 18 x 18 inch granite plate that I sourced from Grizzly industrial. (online catalog at http://www.grizzly.com/ It weighs nearly one hundred pounds by itself! Note that the 4 adjustable supports are not being used. Instead observe the lead pad/large acorn nut arrangement seen in photo #6.

7)

Photo #7). The Teres with Black Diamond Racing cone feet stands

directly over the Granite.

About Granite. It too resonates. It

rings with a low frequency vibe that has a long sustain when properly

excited. Everything, it seems, has resonance. Couple this directly to

your turntable and expect the combination to produce even greater

resonance than each would by itself. It certainly does not dampen

vibrations. But, what the hell, I gave it a try anyway. Nice solid

platform that holds what's on top nice and steady and completely

unperturbed by any floor motion. It definitely is solid. Doesn't move

when you bump into it.

config 2) Granite plate (3" x 18" x 18")

over lead pads that were laid flat over the frame and large acorn nuts

as cones. (photos 6 & 7) There was an apparent improvement in bass

weight. And there was a bit less background silence (more low frequency

rumble) compared to the first configuration with just the Neuance over

the rack, but the bottom end (bass weight) foundation of the sonic

output seemed desirable compared to any previous holding method I'd used

with the Teres.

Also, the weight of the granite plate (100 lbs)

seems to have greatly tamed the frame's tendency to transfer noise from

the building structure. After discussion with audio friends it occurred

to me that by increasing the load on the frame, I had altered the

natural frequency of the assembled load bearing structure. (the

structure of the studs themselves)

8)

9)

9)

(click thumbnail to view image full size)

(click thumbnail to view image full size)

Above photos # 8 & 9 placing the Neuance shelf between the granite and Teres. That's better.

10)

Above photo #10: config as of 2/5/05

config 3) Neuance shelf directly over the granite

plate. (photos 8,9&10) Background silence gets quieter but at no

apparent cost to low frequency slam. Midrange and high frequencies

opened up into a more natural and airy presentation. Subtle details

gained improved definition. Closer to it. Subjective observations. No

measurements.

Summary Notes:

Note 1) For the

Teres, this wall rack gave a sonic improvement compared to the previous

shelf that I had made from Home Depot triangular brackets and a sheet of

plywood. Funny how a more solid foundation beneath the TT also gives a

more solid foundation beneath the music it produces. And this supports

the idea that turntables are extremely sensitive to the manner in which

they are situated. This Teres certainly was.

Note 2) Wall

mounting represents a compromise made to compensate for the flimsy

architecture of the building it is in. These days it seems as though

floors are like torsion springs. Walk across the floor and the floor

flexes, almost bounces, under the force of each foot step. Given a more

solid, less flexy floor, I would have preferred a rigid floor mounting

for the turntable. As it is now with the wall rack I can jump up and

down next to this turntable without causing nary a quiver at the stylus

groove interface. However building noises and vibrations do travel

throughout the buildings structure. If you mount your turntable directly

to the wall, preparations must be made to isolate the turntable from

this type of structure born resonance.

Note 3) It seems that the

more solid the foundation beneath the Teres, the more solid the low

frequency output. But care must be taken to ensure that the base support

does not increase rumble levels of the turntable output.

Note 4)

Increasing the mass loading over the frame results in altering the

natural resonant frequency of the load bearing structure. In this case

the effect worked to the positive.

Note 5) heavy lead plate,

while being dense and able to transmit resonance, appears, also, to

present an effective dampening effect to surface born resonance. I don't

mean sheet lead. This is 1/2 inch thick lead plate. And these are

subjective observations made without any measurements to support them.

Note 6) photo #10 shows a different platter mounted to the Teres

than in the other photos. The lead-shot chambered platter was an upgrade

offered by "Teres Audio" through an exchange program. That was a

considerable upgrade over the solid acrylic platter. More about that on

the Teres page.

Footnotes:

** Greater Ranges,

currently is not selling the Neuance Platform Shelves at this time.

Hopefully, if enough of us can talk Ken back into it, he might change

his mind and begin production again.