-edible zone-

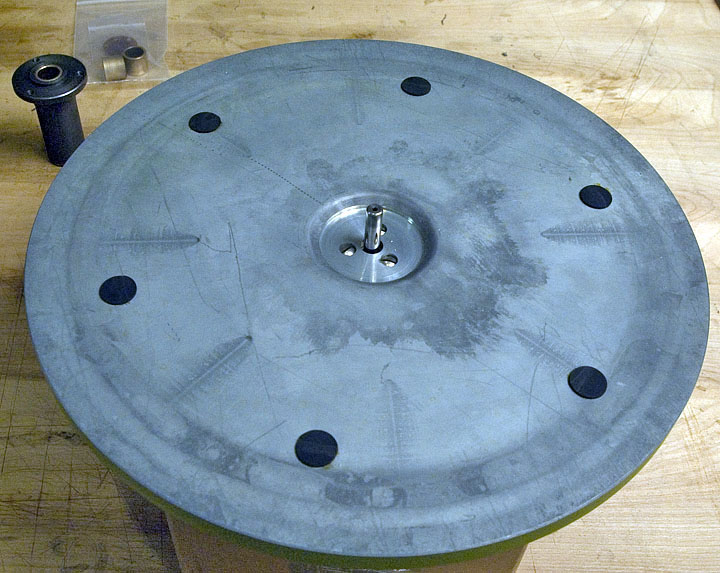

Manufactured by Inca, the same Swiss foundry that

produced the cast chassis and also the zinc platters for later models.

While the heavier iron platter remained standard issue on both

the mk1 and mk2, the non magnetic platter was offered as an option for

those using phono cartridges with stronger magnets to prevent magnetic

attraction from pulling the phono cartridge toward the platter. The

material is 'stabilized cast zinc'.

Part number is CB788,

"turntable with spindle--non-ferrous".

The spindle shaft used for the non-ferrous platter is the same as that used on the ferrous version except for the addition of an adapter plate that fits between the platter and the flange of the spindle. The strobe ring painted on the under flange of the non-ferrous platter calibrates only to 33-1/3 rpm at either 50 or 60 hz.

Above image: the standard 9 lb iron platter

(left) next to the non ferrous platter.(5lb 6 oz). Part number for the

iron platter is: CBE 757 "turntable with spindle -- Ferrous". The strobe

ring painted on the under flange of the ferrous platter calibrates to

all 4 speeds at either 50 or 60 hz.

Other comparisons; Every

surface of the ferrous (iron) platter evidences machined turning marks.

Indicating that every surface has been trued during manufacture. The

non-ferrous platter, in comparison, remains mostly 'as cast' with only

key surfaces having been turned true.

above image: shown for comparison is the TD124 non-ferrous platter (right) and an outer platter (left) for the TD150 mkII. The material for both of these platters is 'stabilized cast zinc'. Note the similarity in texture and color.

Above: Foundry and casting number ID of the TD150 outer platter.