-edible zone-

October 2006

May, 2006

(hint: click on thumbnail for full size image)

(hint: click on thumbnail for full size image)

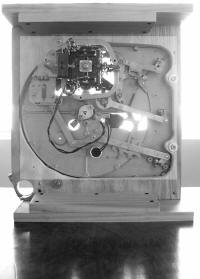

Above photo: recent status: Garrard 301 schedule one, SME 3012 series one, Koetsu Black. Plinth version 3.0 stacked baltic birch ply.

see article on this site: No. 6435 for full details and the story.

(link)

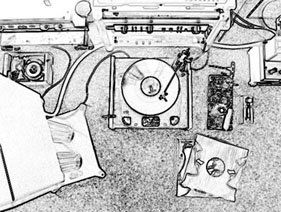

Here are a few snapshots of various pivotal phases in my

Garrard 301 project.

(pre glue)

(pre glue)

The last (below in color... ed.) and most current

version is a Baltic Birch stacked-ply plinth, a high mass design, with a

fairly wide footprint, and a low center of gravity.

On the

subject of gravity, an explanation of the clamping-press procedure is in

order. To get an absolutely square front-edge profile while laminating

with hot hide-glue, it was necessary to design a ‘kneeling press’ that

could be gravity-loaded, clamped, and then up-righted to cure. More

detail about this on the Plinth page of my Garrard Project site, titled

№ 6435 , linked below.

The two earlier plinths here are the simple servicing jig, a utility

plinth which can be positioned on any side for adjustments, even

upside-down, as the tall side panels protect switches and spindle. The ‘armboard’

in this case is a rudimentary bolt-on fitting to facilitate a quick arm

attachment for monitoring & evaluating adjustments.

service jig

service jig

(preliminary checks)

(preliminary checks)

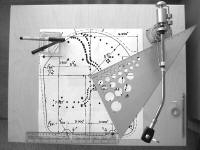

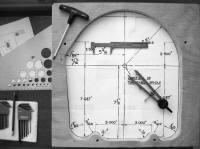

And the high-mass uni-plinth, chiselled out

of a solid section of laminated roof-beam and fitted with a sliding

armboard. This approach allows an internal shape that closely conforms

to the undercarriage of the 301, an aid to absorbing mechanical

resonance.

J.D.