-edible zone-

Jochen's comments and photos:

Hello everybody,

before I start the story of my DIY-Turntable

Projekt, I want to tell something about my past.

I always was

working on my turntables – it started in 72 or 73 when i got my first

Dual.

It was the old one of my parents and the Idler weel was

broken.

So my father and I fixed it and T.REX /Led Zeppelin were

rocking again in 33,3.

Many Players followed in the next 25 years

– from Direct drivers to Belt driven turntables, but I always opened the

cabinet and fixed, tuned or did "something" in this way (changing arms

motors etc.)

I know meanwhile many folks who do the same (after

all: it’s a great thing to tune up turntables!)

So I started 5

years ago to create my own turntable. The Idea was to built an open

System, so it was no problem to change things "here and there".

Let’s start with the Platter:

It’s massive Aluminium / Weight

around 20kg. Diameter 310mm.

High: 60mm.

In the middle of

the Platter, there is a phase for a belt. So there’s the option a belt

can run in the phase or on the normal surface of the platter.

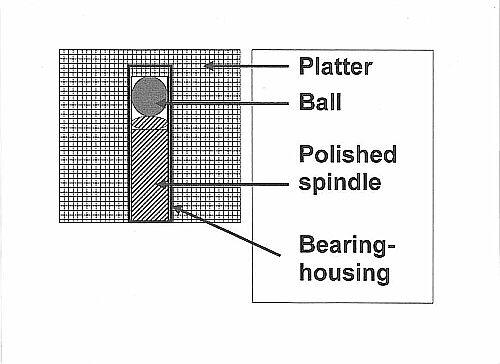

The bearing is link in this picture:

The Cabinet of the player is a block of solid Multiplex Plywood.

The whole cabinet is standing on a combinaton of 4 brass / rubber

feet.

On the right side there’s a plate of solid steel fixed on

the Cabinet.

On this plate several bases for different Tonearms

can be changed quickly.

On the Picture you see a 10" selfbuild

arm.

*The angle construction is from an old Elac Arm, some Telefunken

Parts and the rest is DIY.

The base plate of this arm is also

solid steel.

In combination with this arm I use Grados and

Ortofon moving - magnet pickups, but also a Denon dl103 sounds very

good.

The motor section:

As a base I used a block of solid

beech. It’ a good "vibration-killer".

The whole base is standing

on small felt-feet.

On top, the motor is housed in a solid-steel

case.

The motors are always changing: Sometimes Maxon or like on

the picture a motor from an old marantz tape-deck.

Power-suply:

For a power supply, I use a 12v/6.5 Ah accumulator.

*In the past I used different regulated power-supplies, but the

accumulator is the most noiseless solution.

In the beginning I

talked about the string.

A Nylon string of 0.2mm diameter works

very well. I tried thicker rubber belts,

but after all

experiments I landed by the nylon solution.

The platter is

turning so easily, that there are no problems with wow and flutter.

Second Arm – Plate:

On the left side of the turntable,

there’s a wooden plate for a second Arm.

It’s still in

construction and at the end it will carry an old Lenco-Arm (9") from the

70’s.

I tried many materials like brass, solid-steel etc. but

arms like this one

work (for my taste) the best way on a wooden

base.

So if you have any questions, please feel free to send me

an e-mail:

jochen.straceny@t-online.de

Photos and text by

Jochen Straceny